- Sinumerik 810 Ga3 Programming Manual

- Sinumerik 810m Programming Manual Pdf

- Sinumerik 810m Programming Manual Programming

- Sinumerik 810m Programming Manual User

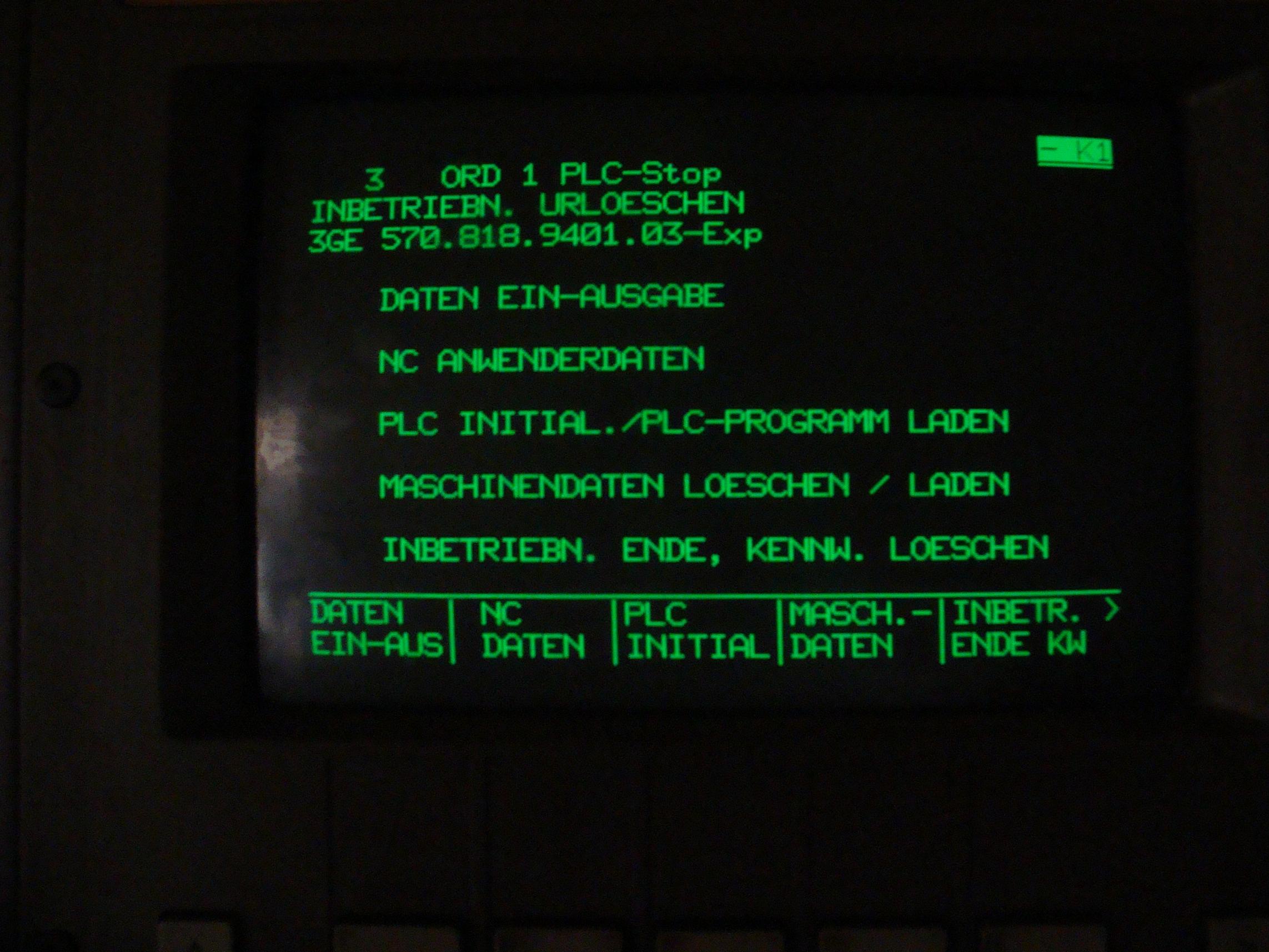

810M 820M SINUMERIK Accessories SINUMERIK Catalog NC 90 Universal Interface SINUMERIK 800 PLC Programming Installation Guide - Instructions - Lists SINUMERIK 810/820 GA 3 Measuring Cycles Version 10 Installation Guide SINUMERIK FB-PLC, Package 1 Tool Management SINUMERIK Spare Parts List SINUMERIK User Shop Floor Storage Module 810/820M 850. The EMCO WinNC SINUMNERIK 810/820 M Milling Software is part of the EMCO training concept on PC-basis. This concept aims at learning the operation and programming of a certain machine control on the PC. The milling machines of the EMCO PC MILL und CONCEPT MILL series can be directly controlled via PC by means of the EMCO WinNC for the EMCO MILL.

A very simple cnc milling program example which will show cnc machinists the use of Siemens Sinumerik milling programming concepts.

This program is written for 4-axis cnc mill, where C is used for rotary table.

But a simple cnc mill can also run this program just remove program block N15

Contents

- Sinumerik Milling Program

Sinumerik Milling Program

Finished Part

Imvu mac os. After the machining is complete, this finished part will look like this

Finished Part

Explanation of G-Code

G00 – Rapid traverse.

G54 – Zero Offset no 1.

G64 – Continuous-path mode.

G90 – Absolute dimensioning system.

G17 – X-Y plan selection.

G42 – Cutter radius compensation activation

G40 – Cutter radius compensation cancel

M03 – Cutter rotation clockwise

S – Spindle speed

F – Axis motion feed

D – Tool no

Contents

WinNC

EMCO WinNC gives cnc machinists/programmers/students the opportunity to install multiple cnc controls software on a single PC/laptop, so they can get trained on all CNC industry controls that are common on the market.

Up to nine different cnc controls can be installed on one single pc/laptop e.g.

- Sinumerik

- Fanuc

- Fagor

- Heidenhain

CNC machinists/programmers can easily download software/manuals from EMCO website for these cnc controls, all links are given below.

SINUMERIK OPERATE

The Sinumerik Operate is part of the changeable control WinNC.

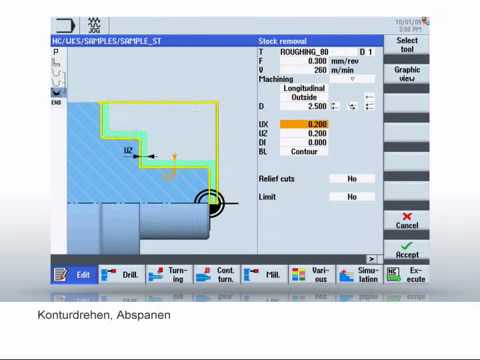

ShopTurn & ShopMill work-step programming

ProgramGUIDE: G code programming, combined with cycle support

DIN/ISO & SINUMERIK high-level language, maximum freedom of programming

Context-sensitive help

Software / Manuals

Download Sinumerik operate software and manuals

SINUMERIK 810D/840D

The Sinumerik 810D/840D is part of the changeable control WinNC.

Sinumerik cnc controls are one of the industry leading cnc machine controls.

Software / Manuals

Download Sinumerik 840D/810D software and manuals

Heidenhain 426

The Heidenhain TNC 426/430 is part of the interchangeable control WinNC.

Software / Manuals

Download Heidenhain 426 software and manuals

FAGOR 8055

The Fagor 8055 is part of the interchangeable control WinNC.

Software / Manuals

Download FAGOR 8055 software and manuals

Fanuc Series 21

The GE Fanuc Series 21 is part of the interchangeable control WinNC.

Fanuc is no doubt the most used and understood cnc machine controls in manufacturing industry.

Sinumerik 810 Ga3 Programming Manual

Software / Manuals

Download Fanuc Series 21 software and manuals

Fanuc Series 0

The GE Fanuc Series 0 is part of the interchangeable control WinNC.

Software / Manuals

Download Fanuc Series 0 software and manuals

EMCO EASY CYCLE

The EMCO EASY CYCLE is a part of the EMCO training strategy. The EMCO EASY CYCLE is suitable for certain conventional turning and milling machines and for EMCO Concept TURN and MILL machines. Previous knowledge in ISO programming is not necessary.

Bluestacks 1 crashing. With an interactive contour programming it is possible to define work piece outlines with linear and circular contour elements.

Sinumerik 810m Programming Manual Pdf

Software / Manuals

Download EMCO EASY CYCLE software and manuals

WIN3D-VIEW

3D graphic simulation with collision control; for turning and milling

Win3D-View is a 3D simulation for turning and milling and is available as an option in addition to the WinNC Control. Graphic simulations of CNC controls are designed especially for industrial experience. Win3D-View displays exceed industry standards. Tools, blanks, clamping devices, and work processes are highly realistic.

The system checks the programmed travel of the tool to prevent collision with clamping devices and blanks. If there is a conflict, a warning is given so that manufacturing processes can be understood and controlled from the very beginning. That’s the aim of Win3D-View: Visualizing, supporting and avoiding costly collisions.

Sinumerik 810m Programming Manual Programming

Software / Manuals

Download WIN3D-VIEW software and manuals

DNC

Vanavil tamil font free. download full version. Remote control of a machine via a software protocol

The DNC-Interface (Distributed Numerical Control) allowes a remote control of the control software (WinNC) via a software-protocol.

The DNC interface creates a connection between a superordinate computer (production master computer, FMS-computer, DNC-host computer etc.) and the control computer of an NC machine. After activation of the DNC operation the DNC computer (Master) takes over the control of the NC machine (Client). The entire production control is completely assumed by the DNC computer. The automation devices such as doors, clamping chuck (collet), sleeve, coolant etc. can be controlled by the DNC computer. The actual status of the NC machine is displayed on the DNC computer.

Sinumerik 810m Programming Manual User

Software / Manuals

Download EMCO DNC software and manuals